Filamento PLA+ Tough Pro AF negro ónix de 1,75 mm ¡Fabricado en EE. UU.!

Filamento PLA+ Tough Pro AF negro ónix de 1,75 mm ¡Fabricado en EE. UU.!

No se pudo cargar la disponibilidad de retiro

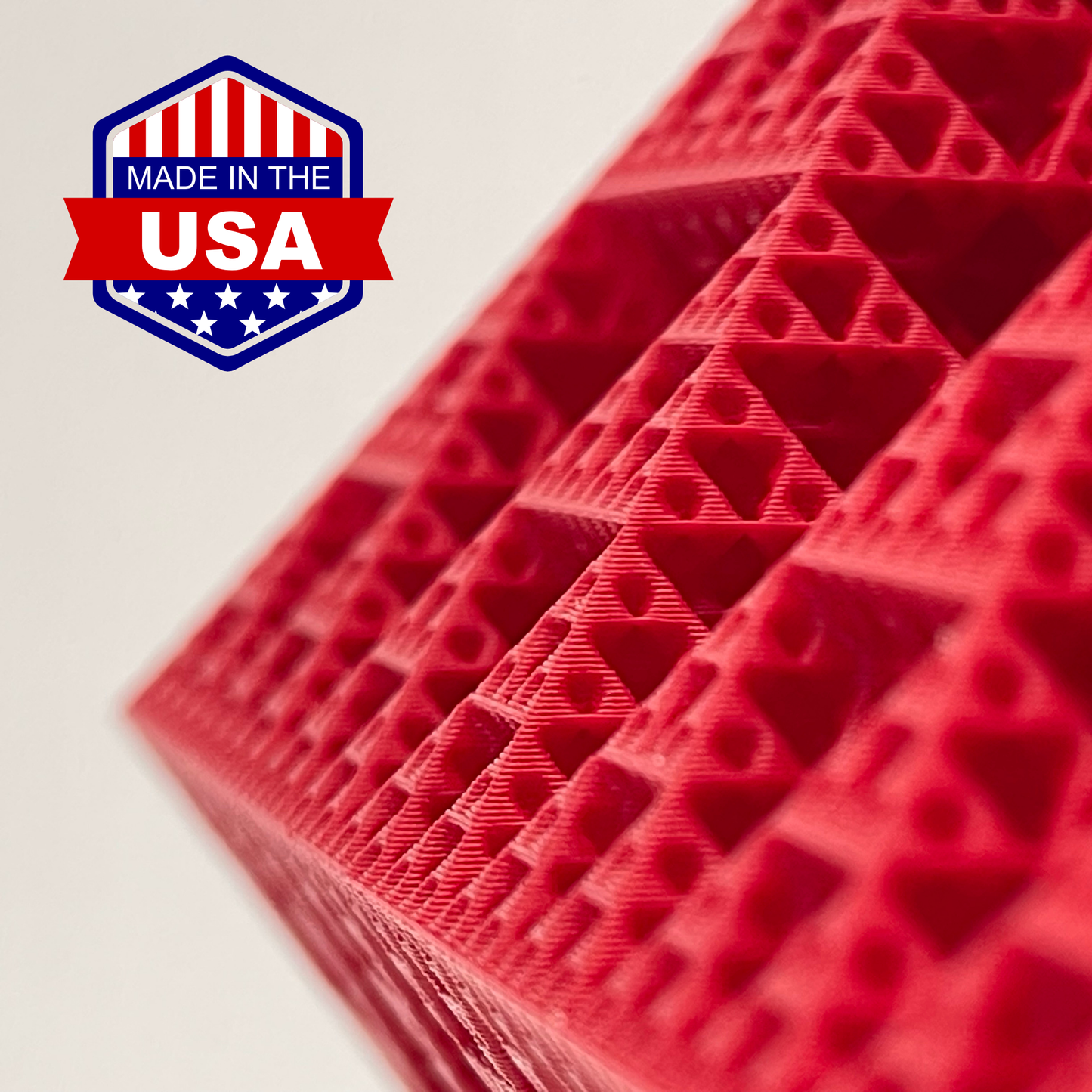

Presentamos nuestro nuevo PLA+ TOUGH Pro. Un PLA resistente de calidad de ingeniería que puede soportar fuertes impactos y altas temperaturas. Directamente desde la placa de construcción, nuestro PLA+ Tough Pro le brinda una resistencia al impacto 8,8 veces mayor que un PLA estándar.

Nuestro Tough Pro PLA+ utiliza resina virgen NatureWorks Ingeo 3D870, que fue diseñada para brindar propiedades térmicas y mecánicas similares al ABS en un paquete de PLA ecológico.

Este grado de PLA se puede recocer después de la impresión para cristalizar aún más el material, mejorando aún más sus propiedades térmicas y mecánicas.

Haga clic aquí para ver nuestra guía sobre cómo recocer sus piezas.

Nuestro Tough Pro PLA+ es un material verdaderamente resistente, diseñado para los trabajos más difíciles. Fabricado con resina PLA Ingeo 3D870 diseñada y fabricada aquí mismo en los EE. UU.; después del recocido, tiene una resistencia al impacto comparable al ABS y una resistencia a la temperatura comparable al PETG, todo en un paquete de PLA de base biológica con las mismas excelentes características de impresión 3D del PLA.

Cada carrete contiene 1 kg (2,2 libras) de filamento, con un diámetro de 1,75 mm y una precisión dimensional de +/- 0,05 mm.

Dimensiones del carrete (ahora compatible con las unidades AMS de Bambu Labs):

- Diámetro interior (ID) = 52 mm

- Diámetro exterior (OD) = 200 mm

- Ancho (An) = 67 mm

- Peso = 200 - 220 g

Recomendamos una temperatura de boquilla de 205-220 °C y una temperatura de lecho de 45-60 °C.

Anteriormente, Onyx Black se llamaba Matte Black. Si recibes un carrete con Matte Black en la etiqueta, ¡es el color correcto!

Descargas:

Print Settings

Print Settings

- Nozzle Temperature: 240 - 270°C

- Bed Temperature: 70 - 100°C

- Speed: 60 - 300 mm/s

Nozzle temperature can vary between 240-270°C depending on desired layer to layer adhesion vs part print quality. Higher nozzle temperatures will result in stronger parts, but may cause lower quality and/or increased stringing.

Part cooling can also vary depending on desired layer to layer adhesion vs part print quality. More cooling will result in better overhangs & bridging, but will decrease the ultimate layer to layer adhesion.

For Bambu Printers: We recommend using the Bambu Labs Gold Textured PEI build plate, or other aftermarket textured PEI build plates, for this material. 70°C should be sufficient for adequate build plate adhesion, going higher than this temperature may cause parts to adhere to the plate too well.

For Bambu Printers: recommended retraction length can vary between 0.8-1.2mm depending on the amount of stringing you experience. For other printers: the default retraction settings for PETG should be sufficient, but total retraction length may need to be increased slightly.

For Bambu Printers: It is recommended to lower your Top Surface print speed to 100-150 mm/s for higher top layer quality.

1kg Spool Dimensions (AMS-Compatible)

1kg Spool Dimensions (AMS-Compatible)

- Filament Weight = 1 kg

- Filament Diameter = 1.75 mm (+/- 0.05 mm)

- Spool Inner Diameter (ID) = 52 mm

- Spool Outer Diameter (OD) = 200 mm

- Spool Width (W) = 67 mm

- Spool Weight = 220 g

Share

Good PCTG Filament. First time I've tried to print with PCTG. But this brand printed pretty well out of the box with minor tweaks to the print profile. Filament seems pretty durable and strong. Can't wait to get more.

My go to filament for everything. Prints a little better than standard PETG and has the added strength and heat resistance.

The filament is fantastic, I've had zero issues printing with this material and I appreciate that its on an AMS compatible spool so I dont have to mess with adapters etc.

Printed some large objects with thin walls without a brim and they held on strong to powder coated PEI sheet. Prints same speeds, cooling and volumetric flow as PETG. Can confirm 1mm thickness holds fluid with no leaks, so the layer bonding is great too.

Received a broken spool that won’t work in my ams. Contacted support and received absolutely no help.

Update from end of December: I wanted to update it and say that the issue I had was rectified. Since receiving the filament, I have had nothing but excellent prints from the product. Excellent pctg.

Eric,

We apologize for the lapse in support! We recently restructured the back end of our support infrastructure, and unfortunately your email slipped throught the cracks. We are sending you a replacement spool.