3D printer filament materials explained

Share

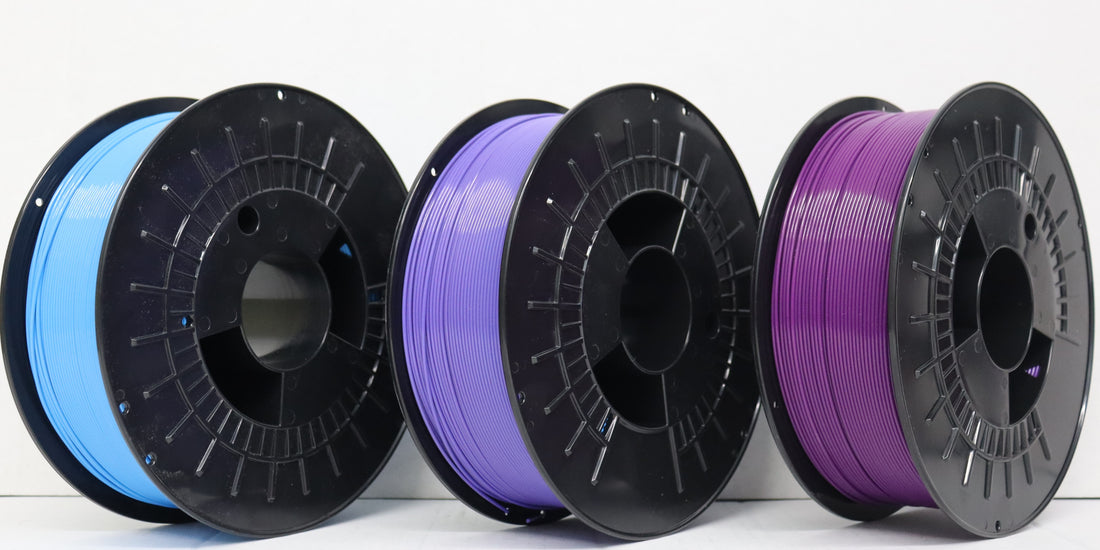

Fused deposition modelling (FDM) 3D printers can use a wide variety of plastic materials with different properties, printability, and use cases. In this article, we’ll cover the strengths and weaknesses of a variety of 3D printer filaments including PLA, PETG, ABS, TPU, Nylon, PC, HIPS, and PVA. For each of these 3D printer filaments, we’ll consider their tensile strength, stiffness, toughness, heat deflection temperature, processing settings, and processability.

PLA (Polylactic Acid)

PLA filament is a biodegradable, thermoplastic material derived from renewable resources like cornstarch and sugarcane. Its strength ranges from 50 to 60 MPa, and its stiffness is between 3 and 4 GPa. PLA has a toughness of 4 to 7 kJ/m², which is relatively low compared to other filaments. The heat deflection temperature is between 50 and 60°C, making it suitable for indoor applications but not for high-temperature or outdoor uses like items in a car in hot climates. In terms of processing settings, the nozzle temperature for PLA ranges from 190 to 220°C, and the bed temperature is between 40 and 60°C. PLA is easy to print with, has minimal warping, and does not require a heated bed, making it a popular choice for use in 3D printing. Additionally, PLA is available in a wide variety of colors and finishes, allowing for diverse and visually appealing prints.

PETG (Polyethylene Terephthalate Glycol)

PETG filament is a glycol-modified version of PET, which offers a balance between the ease of printing and the mechanical properties of the printed parts. PETG has a strength of 40 to 50 MPa and stiffness between 2 and 3 GPa. Its toughness ranges from 15 to 20 kJ/m², providing good impact resistance. PETG has a heat deflection temperature of 70 to 80°C, which is higher than PLA but lower than ABS. The processing settings for PETG include a nozzle temperature of 230 to 250°C and a bed temperature of 70 to 90°C. PETG is relatively easy to print with, as it has minimal warping and good layer adhesion. It also offers good chemical resistance and is food-safe, making it suitable for various applications, including food containers and other household items.

ABS (Acrylonitrile Butadiene Styrene)

ABS filament is a petroleum-based thermoplastic with good strength, ranging from 40 to 50 MPa, and stiffness between 2 and 3 GPa. Its toughness is relatively high at 15 to 30 kJ/m², which makes it suitable for parts that need to withstand impacts. ABS has a heat deflection temperature of 85 to 100°C, allowing it to be used in applications with higher temperature requirements. The processing settings for ABS require a nozzle temperature between 220 and 250°C and a bed temperature of 80 to 110°C. ABS can be more challenging to print with than PLA due to its tendency to warp and its requirement for a heated bed. ABS also produces a lot of fumes during printing, so printing in a well ventilated room is important. However, ABS is popular for its durability, chemical resistance, and ability to be easily post-processed using techniques like sanding, drilling, and gluing.

Nylon

Nylon filament is a strong, flexible, and durable thermoplastic with a strength ranging from 45 to 100 MPa and a stiffness around 2 GPa. Its toughness is quite high, ranging from 80 to 150 kJ/m², making it suitable for applications requiring impact resistance and flexibility. The heat deflection temperature for Nylon varies between 120 and 160°C, making it suitable for various temperature requirements. The processing settings for Nylon include a nozzle temperature of 250 to 270°C and a bed temperature of 70 to 100°C. Printing with Nylon can be challenging due to its sensitivity to moisture, which requires proper storage and drying before printing. Despite these challenges, Nylon is popular for its wear resistance, chemical resistance, and self-lubricating properties, making it ideal for functional parts, such as gears, bearings, and hinges.

PC (Polycarbonate)

Polycarbonate filament is a strong, tough, and transparent thermoplastic with a strength of 50 to 75 MPa and a stiffness between 2 and 3 GPa. Its toughness ranges from 25 to 40 kJ/m², which makes it suitable for applications requiring impact resistance. PC has a heat deflection temperature of 130 to 145°C, allowing it to be used in high-temperature applications. The processing settings for PC include a nozzle temperature of 260 to 310°C and a bed temperature of 90 to 120°C. Printing with PC can be difficult due to its high printing temperature requirements and its tendency to warp, requiring a heated bed and an enclosed printer. However, PC is popular for its excellent transparency, impact resistance, and dimensional stability, making it suitable for various applications, such as automotive components, lighting fixtures, and protective covers.

HIPS (High Impact Polystyrene)

HIPS filament is a versatile thermoplastic with a strength of 35 to 50 MPa and a stiffness between 1 and 2 GPa. Its toughness ranges from 10 to 20 kJ/m², providing moderate impact resistance. HIPS has a heat deflection temperature of 95 to 105°C, making it suitable for indoor applications and some outdoor uses. The processing settings for HIPS include a nozzle temperature of 220 to 240°C and a bed temperature of 80 to 110°C. HIPS is relatively easy to print with, as it exhibits minimal warping and good layer adhesion. HIPS can also be used as a dissolvable support material when printing complex geometries using ABS, as it can be dissolved in limonene. It is popular for its low cost, ease of post-processing, and applications like packaging materials, toys, and model making.

TPU (Thermoplastic Polyurethane)

TPU filament is a flexible, rubber-like material that comes in a variety of strengths and stiffnesses. It’s strength can range from 30 to 45 MPa and a stiffness between 0.5 and 2 GPa. Its toughness is impressive, ranging from 50 to 200 kJ/m², which makes it ideal for applications requiring flexibility and durability. The heat deflection temperature for TPU is between 45 and 60°C, indicating its suitability for indoor use but not high-temperature environments. TPU's processing settings include a nozzle temperature of 220 to 250°C and a bed temperature of 50 to 80°C. TPU can be challenging to print with, as its flexibility may cause issues with extrusion and retraction, requiring fine-tuning of the print settings. However, TPU is popular for its elasticity, abrasion resistance, and ability to produce parts like gaskets, seals, and protective cases.

PVA (Polyvinyl Alcohol)

PVA filament is a water-soluble thermoplastic with a strength of 10 to 20 MPa and a stiffness between 0.5 and 1.5 GPa. Its toughness ranges from 5 to 15 kJ/m², which is relatively low compared to other filaments. PVA does not have a specific heat deflection temperature, as it is primarily used as a support material. The processing settings for PVA include a nozzle temperature of 180 to 210°C and a bed temperature of 40 to 60°C. Printing with PVA can be challenging due to its sensitivity to moisture, which requires proper storage and drying before printing. However, PVA is popular as a support material for complex geometries, as it can be dissolved in water, leaving the main part clean and free of support structures.