How to fix 3D printer bed adhesion issues

Share

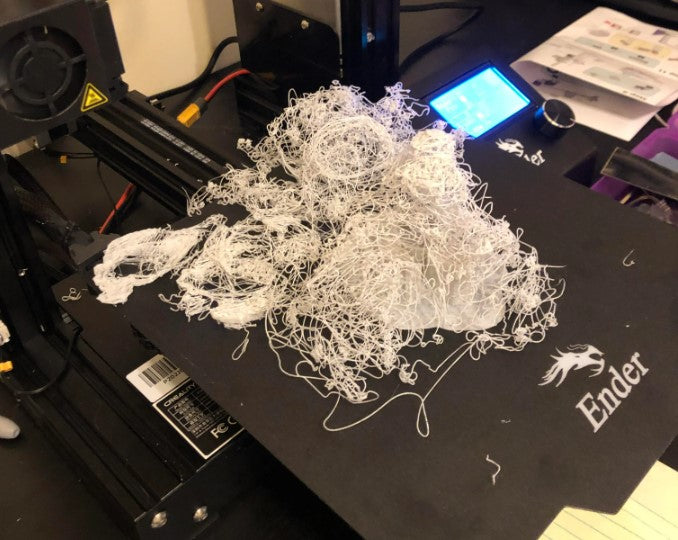

Getting good bed adhesion is one of the most difficult and important things about 3D printing. To print without bed adhesion will open the door to warping at best and at worst summons the loathsome spaghetti monster. Here's a checklist that can help you maintain the best bed adhesion:

- Check bed leveling: Make sure the print bed is level by watching it put down the first layer. The first layer should be flat on top and have no gaps between extrusion lines. If the nozzle is too far from the bed, there will be gaps between the extrusion lines and the extrusion lines won’t be pressed firmly to the bed. If the nozzle is too close to the bed, the extrusion lines will appear thin and too transparent. The extrusion lines will have more of a U shaped cross section instead of the desired rectangular cross section. If it’s possible, adjust the bed level real time as the first layer goes down, so that you can see the quality of the first layer as you make adjustments and get instant feedback. The correct bed leveling process depends on the machine.

- Clean the bed: Make sure the bed is clean and free from any debris or loose plastic. For PEI and glass print beds, wipe the bed with acetone to remove any plastic and then wipe it again with isopropyl alcohol to remove all remaining residue. Acetone can dissolve some materials, so skip the acetone wipe if you’re not sure whether your bed material can handle it.

- Adjust bed temperature: A heated bed keeps the plastic warm, so that shrink as much. This reduces thermal stresses at the interface between the print and the print bed, so that the print adheres to the bed. Adjusting the bed temperature can help improve bed adhesion.

- Use a bed adhesion aid: Use a bed adhesion aid, such as glue stick or hairspray, to increase the adhesion strength between the print bed and the print. These aids can be a bit messy, and the bed should be cleaned periodically to prevent debris buildup, but many people find them to be the best solution for guaranteeing bed adhesion.

- Adjust first layer settings: The first layer of your print is the most important layer. The first layer often has unique settings to improve bed adhesion. Some settings to consider adjusting are: layer height, layer thickness, print speed, and fan cooling. The first layer is often printed thicker, taller, slower, and with less fan cooling than subsequent layers.

- Use a raft or skirt: If you're still having trouble, try using a raft or skirt. A raft is a thin layer of filament that sits between the bed and the print, providing a more secure base for the print to stick to. A skirt consists of layers that surround the base of the print to hold the prints edges down. These features improve bed adhesion, but add print time, filament, and may require some additional post processing after the 3D print is complete.

By following the above steps, you should be able to diagnose why 3D prints aren't sticking to your 3D printer bed and troubleshoot the issue. Please leave comments and suggestions below!