How to fix layer shifting

Share

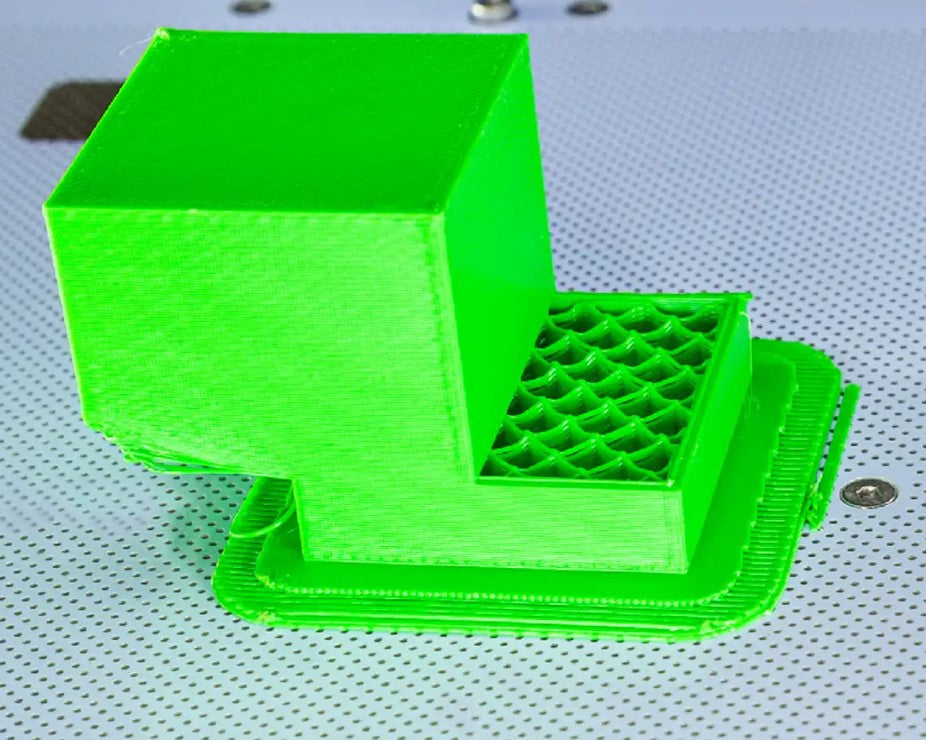

Layer shifting is a problem that happens when layers in a print are skewed or misaligned print. This is typically caused by the hotend’s nozzle catching on the print and getting momentary caught until the nozzle’s heat melts the plastic it is in contact with. At this point, the hotend is released, but at this point it is too late, since the steppers have already unknowingly missed a few steps. We’ll go into detail on steps for fixing this problem below:

- Check the printer's power transmission: Ensure that the belts, pulleys, and other moving parts are tight and correctly aligned. Exactly how you do this depends upon your printer. Belts should feel tight, but not so tight that the belt seems like it could snap or press bearings into excessive friction.

- Check the print bed: If the print bed is not level (particularly if the nozzle is too close to the bed) it becomes more likely that the 3D printer’s nozzle catches on the 3D print and the motor skips a step or the power transmission hops a gear. Make sure the bed is level and adjust the nozzle height to ensure the perfect level throughout the entire printing area of your 3D printer’s bed!

- Check the stepper motor voltage: Warning: This is definitely an advanced a riskier operation. The stepper motor voltage is often controlled by the stepper driver. If the voltage isn’t high enough, the stepper motor may not be able to produce enough torque, but if the voltage is too high, the stepper or driver could overheat. Check how much voltage your stepper should get through the driver and figure out where the motor drivers are located on your 3D printer’s control board. Measure the voltage to see if you’re actually getting the right voltage. As always with circuit boards, be careful to prevent debris from getting on the circuit board and make sure you don’t short anything on accident.

- Check your printer’s firmware: Note: This probably isn’t your problem unless you’ve manually installed the firmware on your printer. Your printer’s firmware specifies the position of your nozzle in X, Y, and Z when your printer homes. If your firmware has the incorrect distance between the home position and the print bed, your printer may miss some of the print bed, and your printer may ram the hot end into a structure. This can damage your printer, and the steppers will skip some steps at the very least resulting in a layer shift.

- Reduce print speed: The mechanical power transmission (steppers, threaded rod, etc) must work harder for the printer to print at higher speeds. This stresses the printer and can lead to belts slipping or stepper motors missing a step. Slowing down the print speed may be just the thing for fixing layer shift.

- Increase cooling: High-temperature prints can cause the plastic to soften and warp, which can result in bumps and inaccuracies in the print that snag the hot end. Increasing the cooling on the printer can help prevent this problem.

- Consider upgrading the printer: Let’s face it – some manufacturers are hyper focused on minimizing cost instead of improving quality and customer experience. Every corner was cut - out of tolerance. Some printers have alignment and stiffness problems that make it very difficult to figure out how to make them work well. If you think this describes your printer, then we recommend you cannibalize those stepper motors and 80/20 extrusion to build a giant robot. Oh, and get a new printer.

This list covers the most common causes of layer shifting. If this helped you, please tell a friend! If it didn’t help you, please drop in the comments what your solution was. Thanks!